Top 10 Tips for Silt Fence Installation Best Practices?

Silt fence installation is crucial for effective erosion control on construction sites. It helps prevent sediment runoff and protects water quality. However, improper installation can lead to failures, causing more harm than good. Understanding best practices is essential for success.

Many factors influence the effectiveness of silt fences. Site conditions, such as soil type and rainfall patterns, play significant roles. Additionally, the quality of the materials used is critical too. A poorly installed silt fence may collapse or allow sediment to escape, undermining its purpose.

In our quest to ensure proper installation, it’s important to reflect on past experiences. Learning from mistakes can guide improvements. We aim to provide practical tips that encourage effective silt fence installation while promoting environmental responsibility. Engaging in thoughtful planning and execution can make a difference.

Understanding Silt Fences: Definition and Purpose in Erosion Control

Silt fences are essential tools in controlling erosion on construction sites. They act as barriers, allowing sediment to settle while water flows through. This process helps prevent soil loss, protecting nearby waterways from contamination. Understanding their purpose is crucial for anyone involved in land development.

Installation of silt fences isn't always straightforward. Many factors can affect their effectiveness. Soil type plays a significant role. For example, sandy soils may require deeper trenching for proper installation. The placement of the fence should also consider water flow direction. A misaligned fence can lead to ineffective erosion control.

Proper care should be taken during and after installation. Observing the fence for signs of failure or tear is important. Fencing can become overwhelmed during heavy rains. This can prompt sediment overflow, which defeats the fence's purpose. Regular inspections and maintenance are required to ensure long-term effectiveness. It’s a simple action yet often overlooked.

Key Materials: Selecting the Right Fabric and Stakes for Durability

When it comes to silt fence installation, selecting the right fabric and stakes is crucial. High-quality fabric can significantly enhance durability. Look for woven or non-woven geotextiles that can withstand harsh weather. The fabric should ideally have a high puncture resistance. Consider the type of soil on your site. Different soils may require different fabric types for effective filtration.

Choosing the right stakes is equally important. Wooden or metal stakes can provide the necessary support for your silt fence. Make sure the stakes are long enough to penetrate the ground deeply. This depth ensures stability even in heavy rains. Proper installation requires the stakes to be spaced adequately along the fence. Improper spacing may lead to sagging or even fence failure.

Remember to pre-soak the filter fabric before installation. This technique can help with compaction and enhance performance. Regularly inspect the installed silt fence too. Look for any signs of wear or failure. Ignoring these aspects can lead to larger erosion problems. Sometimes it’s easy to overlook these details, but they are vital for long-term effectiveness.

Site Preparation: Essential Steps Before Installing Silt Fences

Site preparation is crucial before installing silt fences. Clear the area of debris, rocks, and vegetation. This helps achieve a smooth installation. Measure the site carefully to determine where the silt fences will be placed. Sometimes, miscalculations lead to insufficient coverage. Testing soil moisture levels can also be beneficial here. Wet soil can undermine the fence's effectiveness.

After preparing the site, mark the planned boundaries. Use stakes or flags for visibility. This step ensures the installation aligns with your project’s water management plan. It's vital that the silt fence is on the contour of the land. Misalignment can result in water pooling and soil erosion. Reflect on the alignment often during installation. Relying too much on initial measurements could mislead you. Always be ready to adjust as needed to ensure optimal function.

Top 10 Tips for Silt Fence Installation Best Practices

Proper Installation Techniques: Ensuring Effectiveness and Compliance

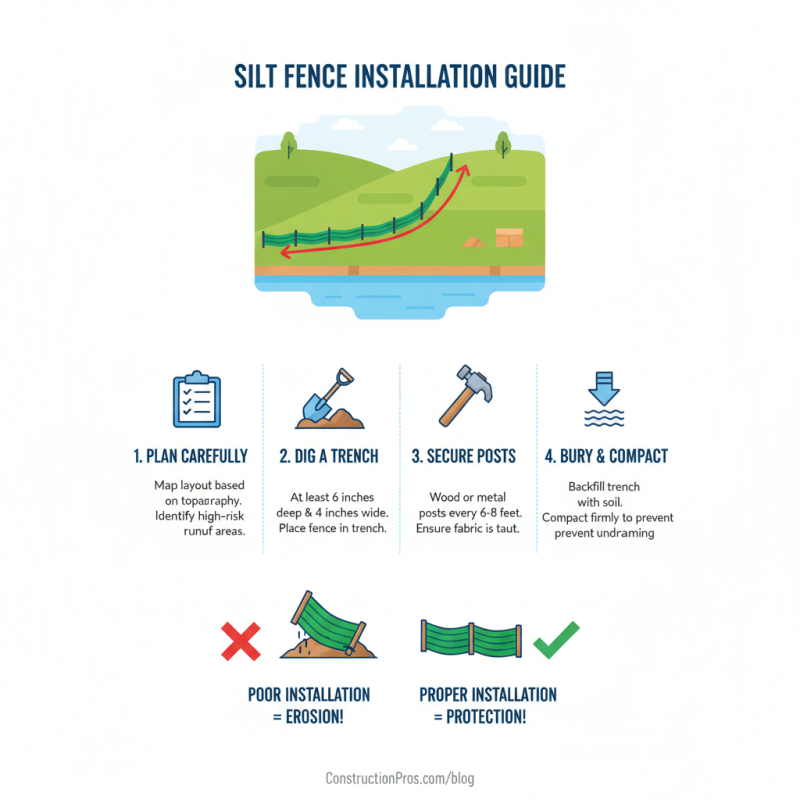

Proper installation techniques are crucial for the effectiveness of silt fences. A poorly installed fence can lead to erosion and sediment runoff. It’s essential to start with a good plan. Determine the layout based on the site’s topography. Ensure the fence is placed in areas with the highest risk of runoff.

Before digging, clear the area of debris. This allows for better soil contact. When installing the fence, bury at least one foot of the bottom. This helps the fence stay upright and prevent sediment from flowing underneath. Regular inspections are important. Check for signs of sagging or breaches after heavy rain.

Here are a few tips to enhance installation. Ensure the fence material is strong enough. Weak materials can collapse easily. Use stakes that provide adequate support. Flimsy stakes will not hold up against water pressure. Timely removal and proper disposal of accumulated sediment is key. Periodically reassess the installation for compliance. Adjustments may be necessary to maintain effectiveness.

Maintenance and Inspection: Guidelines for Long-Term Performance

Proper maintenance and regular inspection are crucial for the long-term performance of a silt fence. Over time, sediment buildup can compromise its effectiveness. Inspect the fence frequently after heavy rain. Look for signs of sagging or erosion. If you notice any damage, take immediate action.

Cleaning needs to be routine. Remove accumulated silt and debris promptly. This keeps the fence functional and prevents overflow. You might need to replace sections if they become too damaged. Performing repairs on time is vital. Neglecting small issues often leads to bigger problems.

Consider the installation location. Factors like slope and soil type affect efficiency. Ensure the fence follows the natural contour of the land. Poor placement can lead to frequent maintenance issues. It's essential to reflect on these aspects regularly. Making adjustments where necessary is part of effective management.

Related Posts

-

Essential Tips for Silt Fence Installation in 2026

-

What is a Silt Fence and How Does It Work for Effective Erosion Control

-

Understanding What Silt Fence Installation Is and How It Works Effectively

-

Best Paver Sealer Options for Longlasting Protection and Durability

-

2025 Top 10 Garden Weed Barriers: Enhance Your Garden with Proven Protection Solutions

-

Best Weed Fabric Types for Garden Control and Sustainability Guide