Ultimate Guide to Geotextile Fabric Types Uses and Benefits

Geotextile fabric has become an integral component in various construction and landscaping applications, providing innovative solutions to a myriad of challenges. This durable material is designed to enhance soil stability, manage water flow, and prevent erosion, making it essential in projects ranging from road construction to agricultural practices. The versatility of geotextile fabric allows it to be tailored to meet the specific requirements of different environments, ensuring its effectiveness across multiple uses.

In this ultimate guide, we will delve into the different types of geotextile fabric, exploring their unique properties and benefits. Understanding the various applications of these fabrics can help engineers, contractors, and landscape designers make informed choices that enhance the longevity and performance of their projects. By examining both woven and non-woven varieties, as well as filtration, drainage, and stabilization functions, readers will gain a comprehensive insight into how geotextile fabric can transform their approach to soil management and construction challenges.

Types of Geotextile Fabrics and Their Properties

Geotextile fabrics are essential materials used in various civil engineering, landscaping, and agricultural applications. They are classified into two main types: woven and non-woven geotextiles. Woven geotextiles are created by interlacing yarns, providing high tensile strength and resistance to puncture, making them suitable for applications requiring reinforcement, such as soil stabilization and erosion control. Their rigid structure allows for efficient load distribution, making them ideal for roads, foundations, and retaining walls.

On the other hand, non-woven geotextiles are produced by entangling fibers through various processes like thermal, chemical, or mechanical bonding. These fabrics are highly permeable, making them excellent choices for applications requiring filtration, drainage, and separation. Non-woven geotextiles are often used in landfill management, silt fences, and as a protective barrier in various applications. The selection of geotextile fabric type largely depends on the specific properties required for the project, including strength, permeability, and durability, ensuring optimal performance in real-world conditions.

Key Applications of Geotextile Fabrics in Civil Engineering Projects

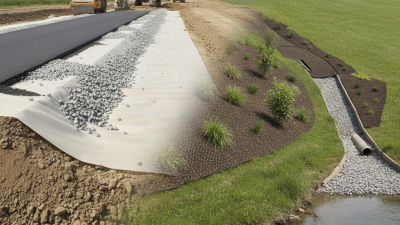

Geotextile fabrics play a crucial role in various civil engineering applications, providing significant benefits in construction and infrastructure projects. One of the primary uses of geotextiles is for soil stabilization. By reinforcing local soils, these fabrics help prevent erosion and support the structural integrity of roadways, embankments, and retaining walls. When installed beneath surfaces, geotextiles improve drainage and reduce the risk of water pooling, enhancing the longevity and performance of these engineered structures.

Another key application of geotextile fabrics is in the filtration of liquids and gases. In projects involving landfill construction or wastewater management, geotextiles act as a permeable barrier, allowing water to pass through while filtering out contaminants. This function is essential for maintaining environmental standards and preventing the leaching of pollutants into surrounding soils and water bodies. Additionally, geotextiles are used in slope protection to minimize washout and ensure that steep terrains remain stable and safe over time. By incorporating these versatile materials, engineers can effectively tackle many challenges encountered in civil construction projects.

Ultimate Guide to Geotextile Fabric Types Uses and Benefits

| Geotextile Fabric Type | Main Uses | Benefits | Key Applications |

|---|---|---|---|

| Non-woven Geotextiles | Separation, filtration | Improved soil stability, erosion control | Highway construction, landfill projects |

| Woven Geotextiles | Reinforcement, stabilization | High tensile strength, durable | Railroad construction, slope protection |

| Composite Geotextiles | Filtration and separation | Combines benefits of woven and non-woven | Coastal construction, dam projects |

| Geogrids | Reinforcement for soil structures | Enhanced load distribution | Roads, embankments, retaining walls |

Benefits of Using Geotextile Fabrics for Soil Stabilization and Erosion Control

Geotextile fabrics are essential tools for enhancing soil stabilization and controlling erosion in various construction and landscaping projects. Their permeability allows water to flow through while retaining soil particles, which is crucial for maintaining the integrity of slopes and other earth structures. By reinforcing soil structure, geotextiles help prevent issues like sediment runoff and landslides, ensuring safer and more durable landscapes.

When utilizing geotextiles for soil stabilization, it’s important to choose the appropriate type based on the specific conditions of your project. For instance, woven geotextiles are excellent for applications requiring high tensile strength, while non-woven options are ideal for drainage and filtration. Tips for successful installation include ensuring the surface is well-prepared, overlapping fabric edges adequately, and securing the fabric properly to withstand environmental stresses.

In terms of erosion control, geotextiles can be used in various applications such as riverbank stabilization, road construction, and green roofs. They promote vegetation growth by providing a stable base for plants, which further aids in soil retention. When installing geotextiles for this purpose, consider factors like site topography and climate conditions to maximize effectiveness. Regular maintenance, such as checking for vegetation growth and fabric integrity, can significantly enhance the longevity of the erosion control measures in place.

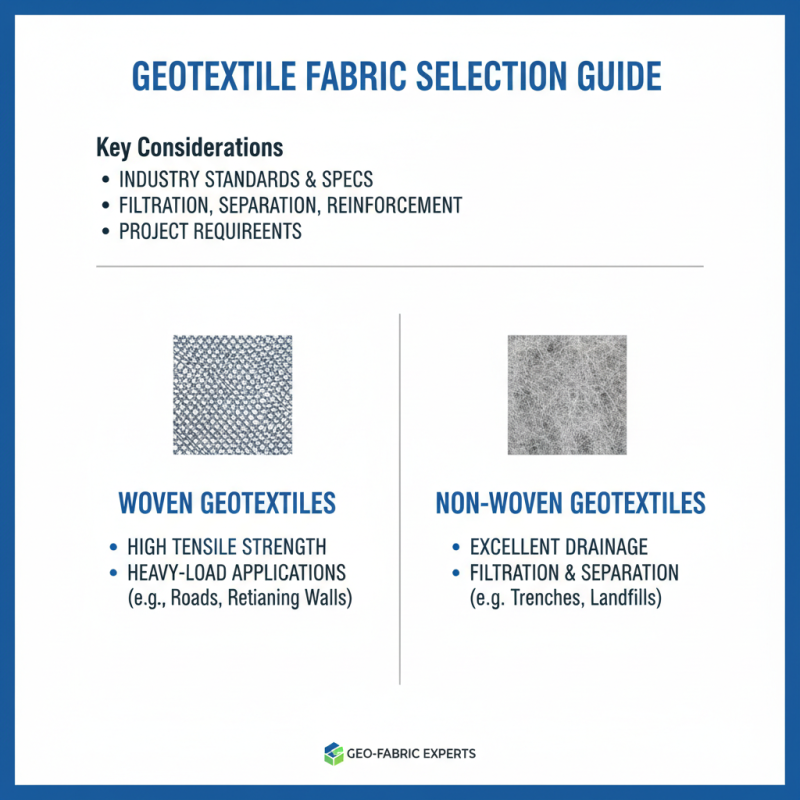

Industry Standards and Specifications for Geotextile Fabric Selection

When selecting geotextile fabrics, understanding industry standards and specifications is crucial. These guidelines ensure that the chosen fabric meets the specific requirements of a project, including filtration, separation, and reinforcement. Geotextiles are categorized into two main types: woven and non-woven, each serving different purposes. Woven geotextiles are known for their high tensile strength, making them ideal for heavy-load situations, while non-woven fabrics are more suitable for applications requiring excellent drainage.

Tips: Always consult the latest industry standards, such as those set by ASTM and AASHTO, when choosing geotextile fabric. This will help you ensure compliance and achieve the desired performance in your project.

Additionally, consider the environmental conditions of your project site. Factors such as soil type, moisture levels, and expected hydraulic loads can significantly influence the effectiveness of geotextile materials. It's essential to select a fabric that not only meets the project's technical specifications but also boasts durability and longevity against environmental stresses.

Tips: Perform a thorough site assessment to determine the appropriate geotextile type and ensure optimal performance throughout the lifespan of the installation. Always prioritize quality and compatibility with the surrounding materials to enhance overall project success.

Environmental Impact and Sustainability Considerations in Geotextile Use

The use of geotextile fabrics has gained popularity in various applications, but it is essential to consider their environmental impact and sustainability. These materials, often made from synthetic polymers, can enhance soil stability and drainage, but their production and disposal raise questions about their ecological footprint. The manufacturing process of geotextiles typically involves significant energy consumption and the release of volatile organic compounds, which can contribute to air and water pollution. Therefore, evaluating the life cycle of these materials is crucial to understanding their overall environmental implications.

Moreover, the sustainability of geotextile fabrics can be improved through the development of biodegradable options and the recycling of existing materials. Innovations in material science are leading to the creation of geotextiles derived from natural fibers or recycled plastics, reducing reliance on virgin resources and minimizing waste. Additionally, implementing more sustainable installation and removal practices can further mitigate their impact on the environment. By prioritizing environmentally friendly alternatives and responsible management approaches, the potential benefits of geotextile fabrics can be harnessed while safeguarding ecological integrity.

Geotextile Fabric Types and Their Environmental Benefits

Related Posts

-

What is Geotextile Fabric and Its Uses in Construction and Environmental Projects

-

How to Choose the Best Paver Sand for Your Landscaping Projects in 2025

-

Understanding What Silt Fence Installation Is and How It Works Effectively

-

What is the Best Paver Sealer? A Comprehensive Guide to Choosing the Right Option

-

What is a Silt Fence and How Does It Work for Effective Erosion Control

-

Best Weed Fabric Types for Garden Control and Sustainability Guide