What is Concrete Sealer and How Does It Work?

Concrete sealers play a crucial role in protecting concrete surfaces. They enhance durability and appearance, making them vital in construction. According to the American Concrete Institute, properly sealed concrete can increase its lifespan by up to 50%. This statistic highlights the importance of using a reliable concrete sealer.

Experts in the industry, like Dr. Emily Larson, frequently emphasize the need for effective sealing. She states, “A high-quality concrete sealer is essential for maintaining the integrity of your surfaces.” With options ranging from penetrating sealers to topical coatings, choosing the right product is critical.

While concrete sealers can effectively prevent damage, not all products deliver the same results. Consumers often face challenges in selecting the best option. Additionally, improper application can lead to peeling and discoloration. The concrete sealing process requires attention to detail and expertise. Choosing a less effective sealer might lead to regret later on. It's crucial to consider all factors before making a decision.

What is Concrete Sealer and its Importance in Construction?

Concrete sealer plays a crucial role in construction. It protects concrete surfaces from moisture, stains, and wear. According to the American Concrete Institute, properly sealed concrete can last up to 30% longer than untreated surfaces. This longevity is essential in both commercial and residential projects.

Sealing concrete surfaces also enhances their appearance. A high-quality sealer can bring out the color and texture of the concrete, making it visually appealing. Many construction professionals emphasize that a well-sealed surface is less susceptible to cracking due to freeze-thaw cycles. This is particularly important in areas with harsh weather.

**Tip:** Always choose a sealer appropriate for your specific project. Not all sealers are created equal. Evaluate the surface conditions and environmental factors. Inadequate sealing can lead to costly repairs down the line. Inspect your concrete regularly. Look for signs of wear or damage. Addressing these issues early can save significant time and money.

What is Concrete Sealer and How Does It Work?

| Dimension | Details |

|---|---|

| What is Concrete Sealer? | A protective coating applied to concrete surfaces to enhance durability and resistance to moisture, chemicals, and staining. |

| Types of Concrete Sealers | Film-forming sealers, penetrating sealers, and high-gloss sealers. |

| Benefits of Using Sealers | Protects against moisture, enhances color and sheen, increases lifespan, and reduces maintenance costs. |

| Typical Applications | Driveways, patios, sidewalks, and indoor concrete flooring. |

| Application Methods | Spraying, rolling, and brushing are common techniques for applying sealers. |

| Drying Time | Typically ranges from 1 to 24 hours, depending on type and environmental conditions. |

| Frequency of Reapplication | Generally recommended every 1 to 3 years depending on exposure and wear. |

| Impact on Appearance | Can enhance the natural color and give a glossy finish or maintain a natural look based on the type used. |

Types of Concrete Sealers: Acrylic, Epoxy, and Polyurethane Explained

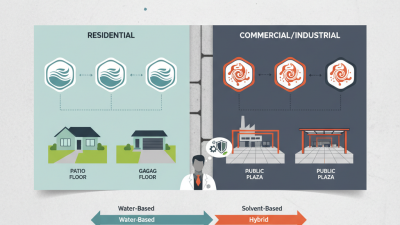

Concrete sealers are essential for protecting surfaces. There are three main types: acrylic, epoxy, and polyurethane. Each has unique properties and uses.

Acrylic sealers are popular. They dry quickly and are easy to apply. These sealers create a thin film on the surface. This film protects against stains and UV damage. However, they may not last as long in heavy use areas. Regular reapplication is necessary, which can be a hassle.

Epoxy sealers offer a stronger, more durable solution. They create a thick, hard layer and are excellent for high-traffic areas. The downside? They can be tricky to apply. A mistake can lead to uneven surfaces.

Polyurethane sealers stand in the middle. They are flexible and resistant to chemicals. But, the application process can be time-consuming. It’s essential to choose the right sealer for your project. Weigh the pros and cons carefully. Each type has its strengths and weaknesses.

How Concrete Sealers Work: Mechanisms of Protection and Bonding

Concrete sealers play a crucial role in protecting surfaces from deterioration. These products work through two primary mechanisms: penetration and film formation. Penetrating sealers seep into the concrete, creating a barrier against water and other harmful substances. They fill the pores in the concrete, which helps prevent moisture damage and stains. According to a recent industry report, over 70% of concrete surfaces experience issues related to moisture intrusion.

On the other hand, film-forming sealers create a protective layer on the surface. This layer acts as a shield against UV rays, chemicals, and abrasion. It helps prolong the life of concrete by maintaining its aesthetic appeal and structural integrity. However, improper application can lead to problems like peeling or blistering. Research indicates that almost 30% of poorly sealed surfaces fail within the first five years.

Both types of sealers provide essential protection. Yet, the effectiveness depends on various factors, including the environment and the condition of the concrete. It's crucial to select a sealer that matches the specific needs of the surface. Understanding these mechanisms allows for better maintenance and longevity of concrete structures.

Application Techniques for Effective Concrete Sealing: Best Practices

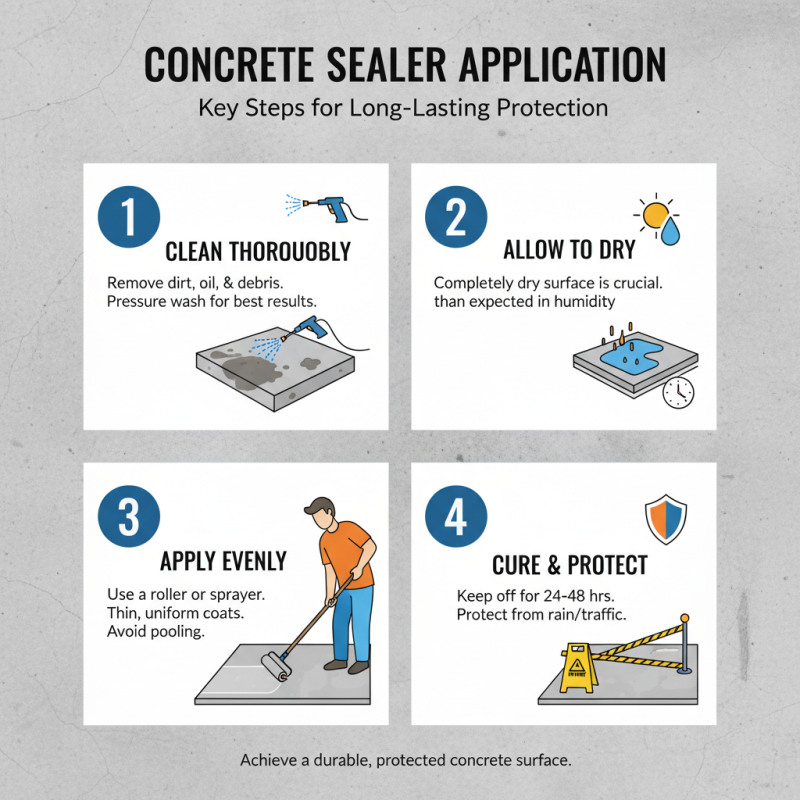

Applying concrete sealer effectively requires careful attention to detail. Start by cleaning the surface thoroughly. Remove dirt, oil, and any debris. A pressure washer can be very helpful here. It's crucial to allow the concrete to dry completely before applying the sealer. This often takes more time than expected, especially in humid conditions.

When applying the sealer, use a roller or sprayer for even coverage. Be mindful of overlapping areas to avoid uneven spots. It’s easy to miss corners or edges, so check these carefully after application. Some people rush this process, leading to poor results. Ideally, two coats of sealer are recommended. The first coat serves as a primer, while the second provides protection.

Timing is important. Ideal conditions include temperatures between 50°F and 90°F. Avoid sealing on windy days, as it can affect the application. Testing a small area first can help gauge drying times and overall appearance. Many overlook this step, resulting in unsatisfactory finishes. Always be ready to adjust your technique based on weather and surface conditions. This level of attention can lead to a durable and appealing finish.

Key Benefits and Limitations of Using Concrete Sealers in Projects

Concrete sealers are essential in many construction projects. They provide a protective layer to concrete surfaces, enhancing durability and aesthetic appeal. One key benefit is their ability to repel water. This reduces the chances of cracking and staining. Sealers also help to prevent the growth of mold and mildew. This is especially important in areas with high moisture levels.

Despite their advantages, concrete sealers come with limitations. Not all sealers are ideal for every surface. Some might cause a slippery texture when wet. This can pose safety risks, particularly in outdoor areas. Additionally, the application process requires careful attention. Rushed application can lead to uneven coverage and compromised performance. It's crucial to consider the climate and usage of the surface before choosing a sealer.

Also, over time, sealers can wear down. Regular maintenance is necessary to ensure continued protection. Some homeowners may forget this, leading to damage. It's a reminder that even great products need care. Balancing the benefits with the drawbacks is key to successful projects. For many, this is a learning curve in the journey of working with concrete.

Related Posts

-

How to Choose the Best Cement Sealer for Your Project Needs

-

Top 10 Best Concrete Sealers for Every Project in 2023

-

Ultimate Guide to Geotextile Fabric Types Uses and Benefits

-

Essential Tips for Silt Fence Installation in 2026

-

2025 Top 5 Innovative Retaining Wall Blocks for Your Landscaping Needs

-

Discover the Best Weed Barrier Options for a Lush and Healthy Garden