Why Choose Driveway Fabric for Your Paving Projects?

Choosing the right materials for paving projects can significantly affect durability and maintenance. Driveway fabric is a popular choice among professionals for its ability to enhance performance. According to a recent report by the American Society of Civil Engineers, using driveway fabric can increase the lifespan of asphalt by 30%. This statistic highlights the value of integrating quality materials in paving.

Industry expert John Harris, a senior engineer at Paving Solutions Corp, emphasizes the importance of this fabric. "When applied correctly, driveway fabric reduces the risk of cracks and other damage." His insight reflects the collective understanding of how critical proper installation is.

However, the choice of driveway fabric is often overlooked. Many homeowners are unaware of its benefits. Some may even question its cost-effectiveness. This hesitation can lead to long-term issues, such as increased repair expenses. Understanding the rationale behind selecting driveway fabric is essential. It could simplify maintenance and prolong the life of your driveway.

Benefits of Using Driveway Fabric in Paving Projects

Using driveway fabric in paving projects offers significant advantages that can enhance durability and prevent common issues. Studies show that about 85% of paving failures relate to subgrade issues. Driveway fabric acts as a barrier, preventing soil and rock from mixing with the surface material. This helps maintain the integrity of the pavement, reducing the risk of cracks and deformation over time. The Geosynthetic Research Institute found that using such fabrics can extend the life of asphalt pavement by 30% or more, which is an impressive statistic.

Additionally, driveway fabric improves drainage. Proper drainage is critical for pavement longevity. By allowing water to flow through while separating the layers, the fabric minimizes the potential for water accumulation. However, not every installation gets it right. Some may forget to properly layer the fabric or apply it in uneven sections. Such errors can still lead to future problems. It's important to ensure that the fabric is laid flat and overlaps adequately to provide maximum effectiveness. When done correctly, these fabrics can transform a paving project, leading to better performance and savings on maintenance.

Why Choose Driveway Fabric for Your Paving Projects? - Benefits of Using Driveway Fabric in Paving Projects

| Benefit | Description | Impact |

|---|---|---|

| Weed Control | Driveway fabric acts as a barrier against weeds, preventing them from emerging through the pavement. | Enhanced aesthetics and reduced maintenance. |

| Soil Stabilization | The fabric provides stability to the subgrade, preventing shifting and settling. | Longer-lasting pavement with fewer repairs needed. |

| Moisture Control | It allows water to drain through while keeping soil and aggregate separate, reducing erosion. | Increased durability of the surface. |

| Cost-Effectiveness | Reduces the amount of gravel or stone needed, saving on material costs. | Lower overall project costs. |

| Easy Installation | Driveway fabric is lightweight and easy to handle, speeding up the installation process. | Faster project completion time. |

Types of Driveway Fabric: Choosing the Right Material

When selecting driveway fabric, understanding the types is crucial. The right material affects durability and maintenance. For many projects, non-woven geotextiles are favored. They provide strength and stability. This fabric allows water drainage while preventing soil erosion.

Another option is woven geotextile fabric. This type offers excellent resistance against punctures and tears. It can support heavier loads, making it ideal for driveways with high traffic. It can be challenging to find the right balance between cost and quality. Cheap options may wear out quickly.

Tips: Always consider your local climate. Some fabrics perform better in wet conditions. Conduct a yard test to see how materials hold up under pressure. Consider the installation process. Some fabrics require more preparation. Doing homework can save time in the long run. Don't rush the decision; it impacts your driveway's longevity.

Why Choose Driveway Fabric for Your Paving Projects?

This chart illustrates the popularity of different types of driveway fabrics used in paving projects. Woven fabric leads the preference, followed by non-woven fabric. Geogrid and polyester fabric are used less frequently, highlighting the importance of selecting the right material for effective paving solutions.

Installation Techniques for Driveway Fabric in Paving

When installing driveway fabric, proper techniques are crucial for durability.

First, ensure the ground surface is clean and graded. Remove debris, rocks, and vegetation. A soft, even base leads to better fabric performance. Studies show that a solid base can increase the lifespan of paving by 30%.

Upon laying the fabric, overlap the edges by at least 12 inches. This prevents soil from seeping through the seams. Proper anchoring is essential. Use landscape staples or pins to secure the fabric in place. A recent report indicates that proper anchoring can reduce fabric shift by 50%.

Trenching around the edges can also be helpful. Clear a section of soil for a tight fit. Although some may skip this step, it enhances the integrity of the install. Observing small details can make a huge difference. Even minor mistakes in placement can lead to uneven settling. This may prompt costly repairs later.

Cost-Effectiveness of Driveway Fabric Over Time

Driveway fabric is a critical component in paving projects, particularly due to its cost-effectiveness over time. By acting as a barrier between soil and asphalt, it prevents the mixture from sinking. This results in fewer repairs and less maintenance, ultimately saving homeowners money. A report by the National Asphalt Pavement Association indicates that using driveway fabric can enhance the lifespan of asphalt by approximately 30%.

Many homeowners overlook the long-term savings when choosing driveway fabric. While the upfront cost may be higher, the durability it offers pays off. The typical maintenance costs associated with unprotected driveways add up significantly. Regular patching and resurfacing can amount to thousands over time. Properly fabric-reinforced driveways often require minimal maintenance in comparison.

Tip: Consider evaluating your soil conditions before paving. If your driveway rests on unstable soil, fabric becomes even more essential. Also, keep in mind seasonal changes. Excessive moisture can undermine a driveway. Even with fabric, regular inspections are important. Neglect can lead to potential damage, diminishing the benefits of your initial investment.

Common Mistakes to Avoid When Using Driveway Fabric

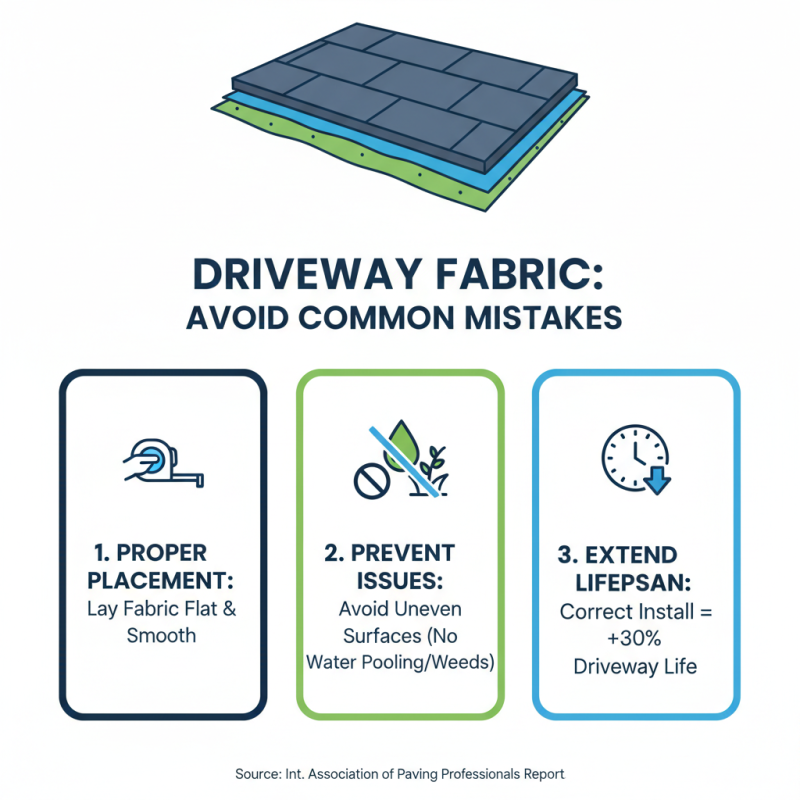

When using driveway fabric, avoiding common mistakes is key. Many people underestimate fabric placement. Installing fabric incorrectly can lead to issues. For instance, fabric should be laid flat. Uneven surfaces can cause water to pool, promoting weed growth. A report from the International Association of Paving Professionals indicates that improper installation can reduce the lifespan of the driveway by up to 30%.

Another common mistake is neglecting to overlap seams. Overlaps should be at least 12 inches. This may seem minor, yet it creates a stronger barrier against soil and weeds. Failing to do this can reduce the fabric's effectiveness. Furthermore, people often forget to keep the fabric clean before laying the gravel or asphalt. Dirt or debris can compromise its function. According to a study, contamination can lead to a 20% decrease in durability over time.

Maintaining drainage is another critical consideration. Fabric should not block water flow. Improper drainage can lead to erosion beneath the surface. This issue is often overlooked, yet it can cause serious long-term damage. Make sure to monitor for any signs of shifting. Small issues can become significant problems if left unchecked. These preventive measures can save both time and money in the long run.

Related Posts

-

2025 Top 5 Landscape Cloth Options for Your Garden Needs

-

Discover the Best Weed Barrier Options for a Lush and Healthy Garden

-

Ultimate Guide to Geotextile Fabric Types Uses and Benefits

-

2025 Top 5 Innovative Retaining Wall Blocks for Your Landscaping Needs

-

Top 10 Tips for Silt Fence Installation Best Practices?

-

2026 Top Weed Barrier Fabric Options for Your Gardening Needs?