How to Choose the Best Cement Sealer for Your Project Needs

When embarking on a construction or renovation project, one critical decision is the selection of the appropriate cement sealer. Whether you are looking to protect a new driveway, enhance the longevity of a basement floor, or preserve the beauty of architectural concrete elements, the right cement sealer can make all the difference. The purpose of a cement sealer is not only to provide a protective barrier against moisture, stains, and environmental damage but also to enhance the aesthetic appeal of the surface it coats.

Choosing a cement sealer involves understanding the specific requirements of your project, including factors such as the type of surface, exposure to weather conditions, and desired finish. Different types of sealers offer various levels of protection and visual effects, making it essential to assess their benefits and limitations before making a selection. This guide aims to help you navigate the various options available, ensuring that you choose the best cement sealer tailored to meet your project needs effectively. By identifying key considerations, such as durability, application method, and maintenance, you can make an informed decision that will extend the life of your surfaces and maintain their appearance.

Understanding Cement Sealers: Types and Functions

When selecting a cement sealer, it’s vital to understand the different types available and their specific functions. Cement sealers generally fall into two main categories:

topical sealers and

penetrating sealers. Topical sealers create a protective layer on the surface of the concrete, safeguarding it from wear, stains, and moisture—making them ideal for decorative concrete surfaces. On the other hand, penetrating sealers infiltrate the concrete, providing internal protection that helps prevent damage from within. According to the American Concrete Institute, the right choice can enhance the longevity of concrete surfaces by 30% or more, highlighting the importance of selecting a sealer that complements the project’s needs.

Tips for choosing a cement sealer include evaluating the specific environment the concrete will be exposed to. For instance, areas with heavy foot traffic or harsh weather conditions may require more robust sealers. Additionally, consider the permeability of the concrete itself. Sealers have varying levels of penetration, and understanding the concrete's porosity can help in selecting the right product. A recent study by the National Ready Mixed Concrete Association indicated that improper sealing can result in significant deterioration, costing homeowners and businesses up to

$2,000 annually in maintenance and repairs.

Another critical factor is the application method of the sealer. Some products are best applied through spraying, while others may require rollers or brushes. Always follow manufacturer guidelines for the best results. Ensure that the surface is properly prepared before application, as contaminants can compromise the effectiveness of the sealer. A clean and dry surface increases adhesion and durability, providing optimal protection for your concrete project.

Factors to Consider When Choosing a Cement Sealer

Choosing the best cement sealer for your project involves careful consideration of several key factors. One primary consideration is the type of cement surface you are working with. According to a report by the American Society of Concrete Contractors, different sealers are formulated for varying cement types, such as polished concrete or exposed aggregate.

For instance, while some sealers are suited for outdoor surfaces requiring enhanced UV protection, others cater to indoor applications, focusing on moisture resistance. Identifying the specific characteristics of your cement surface is crucial in selecting a compatible sealer that will deliver optimal results.

Another important aspect to consider is the environmental conditions in which the sealer will be applied. Data from the Portland Cement Association indicates that temperature and humidity levels can significantly affect the curing and performance of cement sealers. In areas with high humidity or extreme temperature fluctuations, a penetrating sealer, which allows the substrate to breathe while preventing water intrusion, is often recommended. Additionally, understanding the desired finish—whether a glossy or matte appearance—can influence your choice, as different sealers can impart varying aesthetic qualities. Taking these factors into account will help ensure the chosen sealer meets both functional and visual expectations for your cement surface.

Evaluating Your Project Needs and Environment

When selecting the best cement sealer for your project, understanding your specific project needs and environment is crucial. Various factors such as climate, foot traffic, and surface type can significantly influence the performance of your chosen sealer. According to a 2022 industry report from the Concrete Industry Association, nearly 40% of sealing failures are attributed to improper product selection based on environmental conditions. For instance, locations with high humidity may require sealers that offer moisture resistance, while regions with extreme temperature fluctuations should prioritize flexibility and durability.

Tips: Always consider the lifespan of the sealer. Many high-quality sealers provide extended protection, lasting up to 10 years under optimal conditions. Additionally, ensure you evaluate the application method—some sealers are better suited for spray application, while others are designed for rolling or brushing on surfaces, which can affect the evenness of coverage and overall aesthetic.

The environment in which the cement will be used plays a vital role as well. For outdoor projects, UV resistance becomes a top priority, as exposure can lead to discoloration and degradation over time. A 2021 study by the National Concrete Institute found that sealers with adequate UV protection can reduce color fading by up to 50%. Analyzing these environmental factors will guide you towards the most effective product for your specific application, ensuring your project stands the test of time.

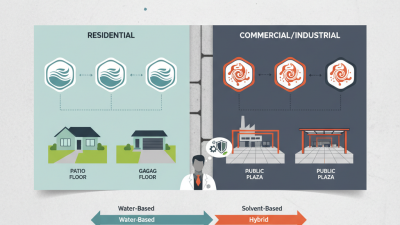

Comparing Sealers: Water-Based vs. Solvent-Based Options

When it comes to choosing the right cement sealer for your project, understanding the differences between water-based and solvent-based options is crucial. Water-based sealers are known for their easy application, low odor, and user-friendly clean-up. They penetrate the surface to protect against moisture and stains while being environmentally friendly. This makes them an ideal choice for indoor projects or areas with poor ventilation. However, they may require more frequent reapplication compared to their solvent-based counterparts.

On the other hand, solvent-based sealers provide stronger protection and are generally more durable in high-traffic areas. They penetrate deeper into the concrete, offering longer-lasting results and better resistance to harsh weather conditions. However, the application process can be more complicated due to their stronger odors and more complex clean-up requirements. Choosing between the two options often depends on the specifics of your project and the level of durability needed.

Tips: Consider the environment in which the sealer will be used. For indoor applications, opt for a water-based sealer for better air quality. For outdoor or high-use surfaces, a solvent-based option might provide the durability you need. Always test the sealer on a small area first to ensure compatibility with your concrete surface. Additionally, check the manufacturer's recommendations regarding application conditions, temperature, and preparation for optimal results.

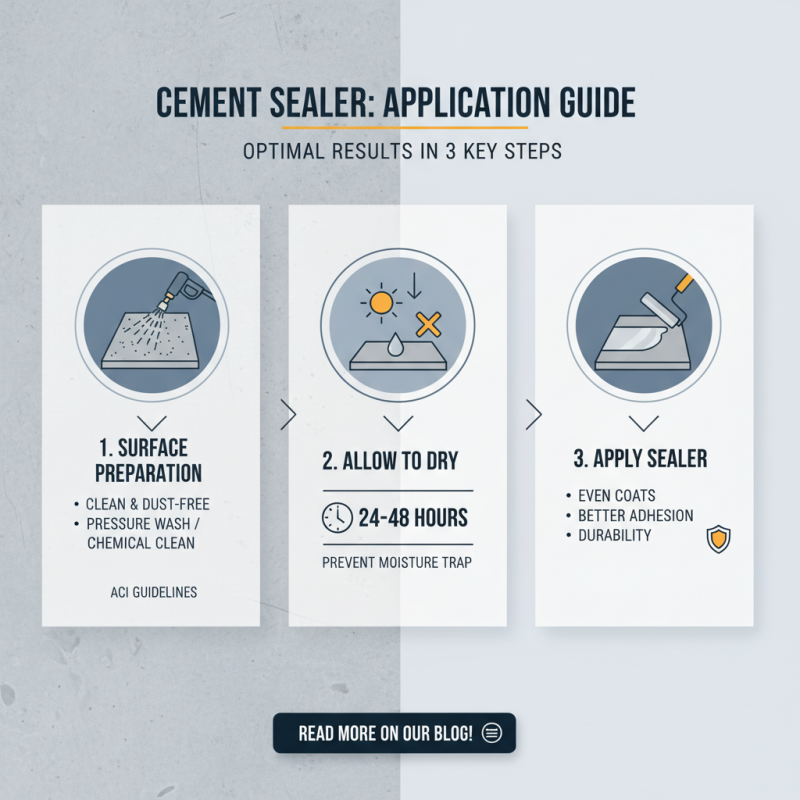

Application Techniques for Optimal Results

When applying a cement sealer, proper application techniques are crucial to achieving optimal results. First, surface preparation is key. According to the American Concrete Institute, a clean, dust-free surface enables better adhesion and effective sealing, reducing the likelihood of peeling or degradation over time. Cleaning methods may include pressure washing or using chemical cleaners, depending on the level of contamination. Additionally, it is essential to allow the surface to dry completely before applying the sealer, ideally waiting 24 to 48 hours to prevent trapping moisture beneath the sealer.

Next, understanding the application method is vital. For larger areas, a roller may be effective, as it can cover substantial surfaces quickly. However, for intricate or smaller regions, a brush or sprayer can provide better control and precision. The National Association of Home Builders recommends applying sealer in thin, even coats to avoid pooling, which can lead to an uneven finish. A second coat may be necessary after the first has cured, generally within the time frame specified by the manufacturer's instructions. By following these techniques, you can enhance the durability and appearance of your concrete surface, ensuring your project meets both aesthetic and functional needs.

Related Posts

-

How to Choose the Best Paver Sand for Your Landscaping Projects in 2025

-

Best Weed Fabric Types for Garden Control and Sustainability Guide

-

Top 10 Best Concrete Sealers for Every Project in 2023

-

What is Geotextile Fabric and Its Uses in Construction and Environmental Projects

-

2025 Top 10 Garden Weed Barriers: Enhance Your Garden with Proven Protection Solutions

-

What is the Best Paver Sealer? A Comprehensive Guide to Choosing the Right Option